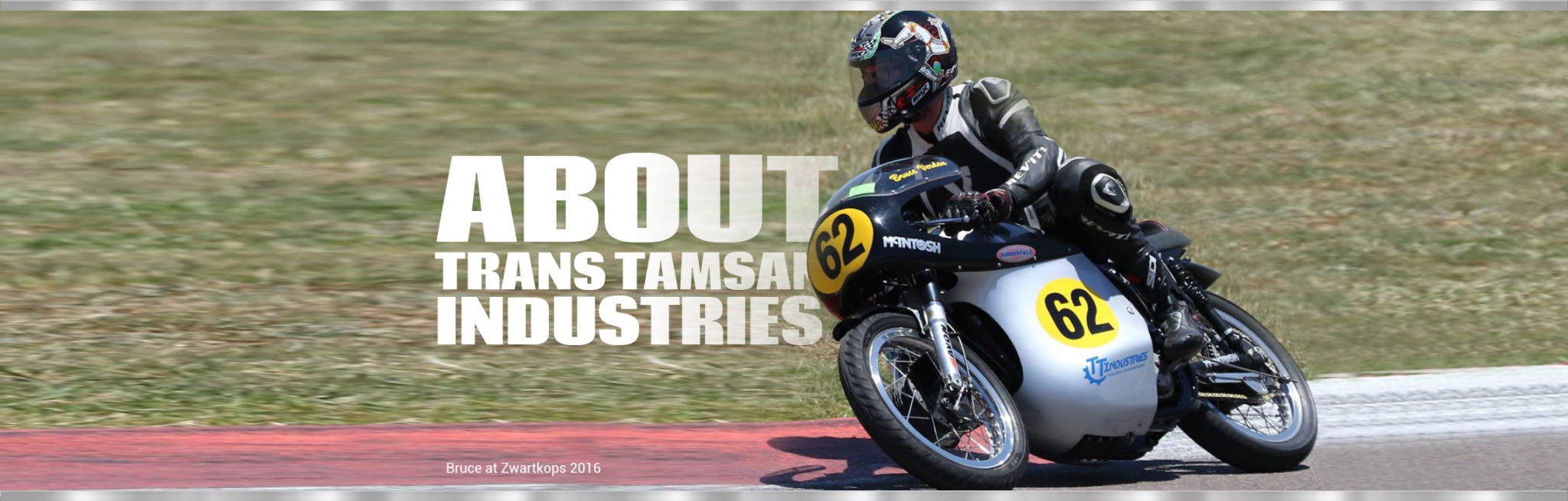

Bruce’s passion for motor racing birthed his motivation to design and manufacture superior gearboxes for both car and motorcycle racing markets. A keen motorcycle racer himself (since his teen years) and the driver of the TTI racing gearboxes Ford race car, Bruce knows what race drivers need out of their gearbox.

Bruce, the Trans Tasman Industries (TTI) founder, began cutting gears more than 30 years ago when serving his apprenticeship on the South African Railways, where he also learned pattern making, moulding and casting. In South Africa in 1986 he started an engineering business manufacturing and packaging machines and components. In 2000 he emigrated to New Zealand and began producing classic motorcycle gear boxes with the equipment he had shipped over from South Africa.

TT Industries, the company, was born in Nelson in 2003 and Bruce started making complete gearboxes for Norton motorcycles. “I made the patterns for cases, designed my own internals and put them in,” he said. They proved a huge success among local riders in 2004 and then started selling rapidly overseas.

Bruce Verdon

That success prompted Bruce to design a similar system for car-based motorsports, a development project that took three years before launching first to the New Zealand race public and then another few years later internationally.

From there the business has gone from strength to strength, winning local business awards in 2016 and growing to nine staff members. Bruce has travelled overseas to market TTI gearboxes in China, Japan and Thailand as well the UK and Australia. Over recent years Russia has proved to be a growing market too.

Some of our amazing TTI staff

Vaughan Wylie

Vaughan is TTI’s Operations and Production Manager. He manages production for all the gearboxes, maintains the inventory system, and ensures that all materials are on hand in order to get customer’s orders started promptly. He is also responsible for assisting customers from initial inquires through to final delivery. Vaughan joined TTI in April of 2019 with more than 11 years of experience in mechanical engineering and technical manufacturing.

Rachel Greig

Rachel, who has an extensive administration, business and retail background, is TTI’s Payroll Manager and accounts payable contact. She also helps maintain inventory with Vaughan, organise events and provide admin support to Bruce and the rest of the staff.

Brett Woollett

Brett is Bruce’s right-hand man. He is the first engineer Bruce employed when the business took off and Brett helps Bruce develop and design as well as helping customers solve technical issues. When he is not designing or problem solving, Brett machines specialist parts on two CNC milling machines.

Shane McGowan

Shane is a highly experienced motorcycle mechanic. He will often answer technical questions regarding our motorcycle gearboxes and troubleshoot fitment and installation issues. He is OCD with product quality and will go the extra mile to ensure customers needs are met.

“Parts fitted great, customer is already back on the track. Thanks heaps for the great service!!!”

Corey Hamilton, Australind Automatics, Australia