Retired Geraldine farmer Gerald Hargreaves is living his dream after…

What smart sequential gearbox racers do for maintenance

Ever wonder how the winners on the race podiums avoid breakdowns and gearboxes being out of action? Do you ever question why you need to replace more parts on your sequential race gearbox regularly than you budgeted for?

If the answer to either of these questions is yes, you need to read this blog. And read on too if you want to continue to avoid costly and unnecessary breakdowns.

Seven maintenance tips to get the best out of your sequential race car gearbox :

- Read the car gearbox manual supplied with your sequential.

- Make sure your gearbox is installed and set up correctly from the start.

- Use the recommended oil.

- If the oil temperature is exceeding 120 degrees Celsius install an oil cooler and pump.

- Keep an eye on oil quality and change after every race meeting.

- Change gears using the clutch smooth and positively.

- Check all bearings and crack test all gears every two seasons generally.

- 1) Read the car gearbox manual supplied with your sequential.

There is a reason gearbox manufacturers usually provide a manual with their product – they want it used correctly and to perform like it was designed. They also don’t want reckless drivers or installers ruining the gearbox and their reputation with it. So read the manual – it is in your best interests too – not doing so could cost you more than you would otherwise need to spend on maintenance. If you are not supplied with a manual or buy a second hand gearbox – ask for one.

- 2) Make sure your gearbox is installed and set up correctly from the start.

Set-up is extremely important and needs to be done correctly even if you are tempted to take short-cuts to get out on the race track. Don’t. You will regret it. Incorrect set-up can be costly and take your race car out of action during race season. A common installation error is not making sure the input shaft fits properly into the spigot bearing – too loose or not reaching the spigot bearing at all. Another installation error is incorrect clutch set-up. The clutch must release when the driver changes down or engages first gear. If reverse can not be selected when the car is idling and your gearbox is in neutral, then you have too much drag on your clutch. The clutch will need to be re-adjusted. Also check the clutch plates are not warped causing drag.

- 3) Use the recommended oil.

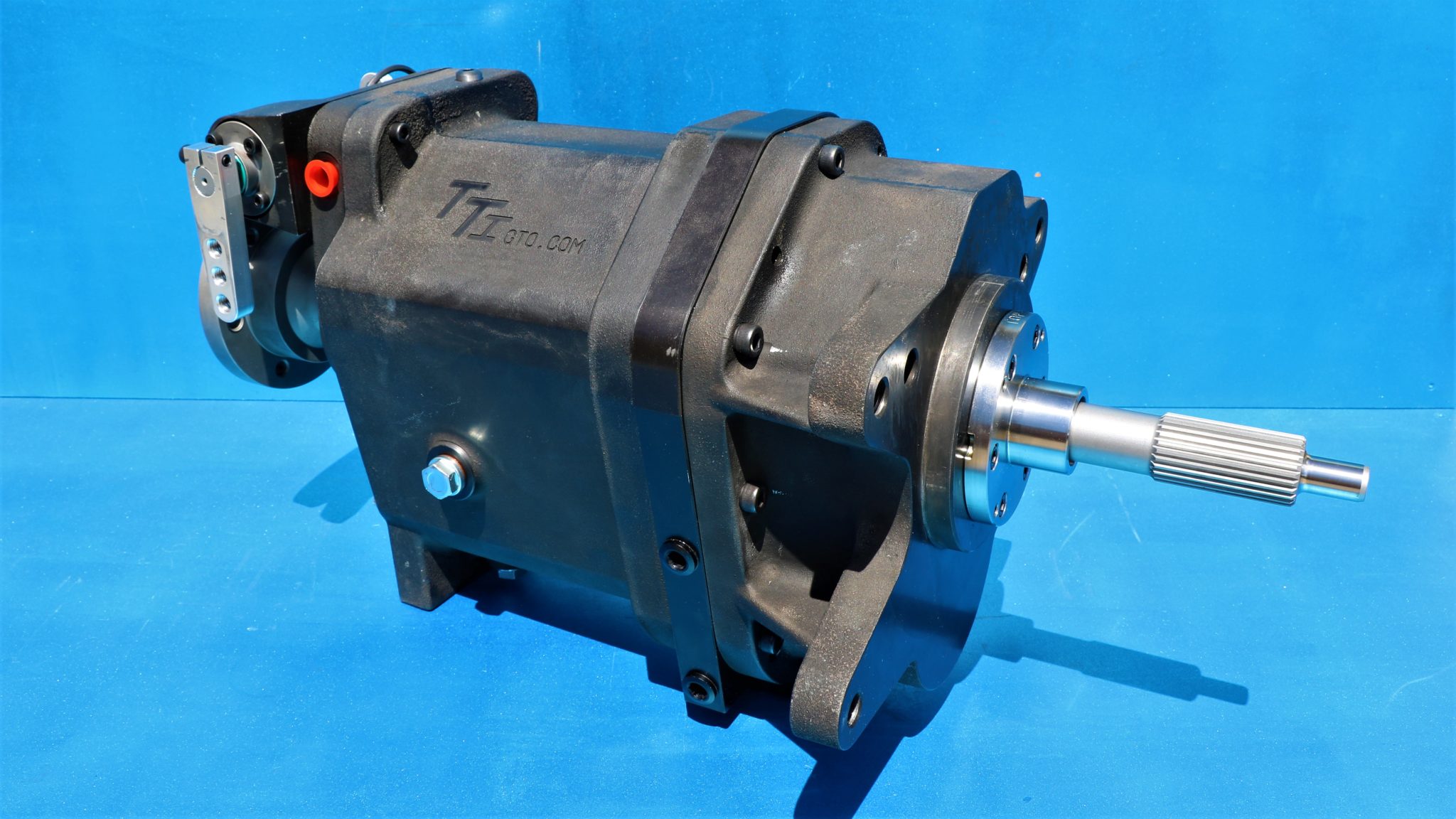

Using the wrong oil can wear out bearings and gears faster than usual, resulting in strange noises and stiff shifting. Eventually the gearbox could seize up resulting in major damage. TTI sequential race gearbox users should make sure they are running Motul Nismo Competition Oil 2189E 75W-140m , or Castrol Axle AP 85W140 or similar spec oil. As outlined in the TTI car gearbox owners’ manual DO NOT use shock proof oils as the oil does not flow through the bearings.

- 4) If the temperature is exceeding 120 degrees Celsius install an oil cooler and pump.

As oil heats over safe levels it will first cause a varnish to form. Then the seals will start to harden. The final step will be transmission failure. You can vastly improve your gearbox’s life by making sure it does not overheat. Changing oil as directed by your gearbox manufacturer will also avoid over heating. As oil ages it starts to break down and loses it capacity to cool the transmission.

- 5) Keep an eye on oil quality and change after every race meeting

TT Industries advises gearbox users to change oil after every race meeting so that drivers can check for any unusual changes. If the dogs are being rounded shavings can appear in the oil. Generally the darker and more opaque the oil the sooner it needs to be changed. Some metal shavings should be expected, but a significant amount of debris could indicate severe internal damage, in which case you should have it serviced as soon as possible. This is one of the most common signs of transmission problems. Never let your oil get to this stage. If not dealt with, the transmission will eventually fail, leaving you with the options of getting it repaired or replaced.

- 6) Change gears using the clutch positively and smoothly

The effective method for changing gear with a sequential gearbox is to load the gear lever with your hand and then lift the throttle foot off and back onto the throttle as quickly as possible. The loaded gear lever will flick through to the next gear before the throttle is re-engaged. To ensure you get the best from your gearbox it is crucial to keep the gear shifting smooth and positive. Watch TTI founder Bruce Verdon demonstrate how to shift below.

When you are changing gears pull the lever backwards for upshift then release between gear changes so that the lever can return to its natural position. The same applies to downshifting by pushing the lever forward and releasing whilst using the clutch. IF YOU ARE DRIFTING DO NOT CHANGE GEARS DURING THE DRIFT. If you drive correctly by changing gears positively and in a co-ordinated fashion, your gearbox dogs will remain in excellent condition.

- (7) Check all bearings and crack test all gears every two seasons generally

Providing you are not rounding the dogs, your gearbox should last you two seasons before you need to check all bearings and crack test all gears. If you are drifting you will need to do this every season. Maintenance also depends on how much power you are putting through the gearbox and how many race miles you are clocking up. The more power your car has and more race miles you do will possibly increase the need for earlier checks.

Visit the TTI website car gearbox page to learn more about TTI race gearboxes.